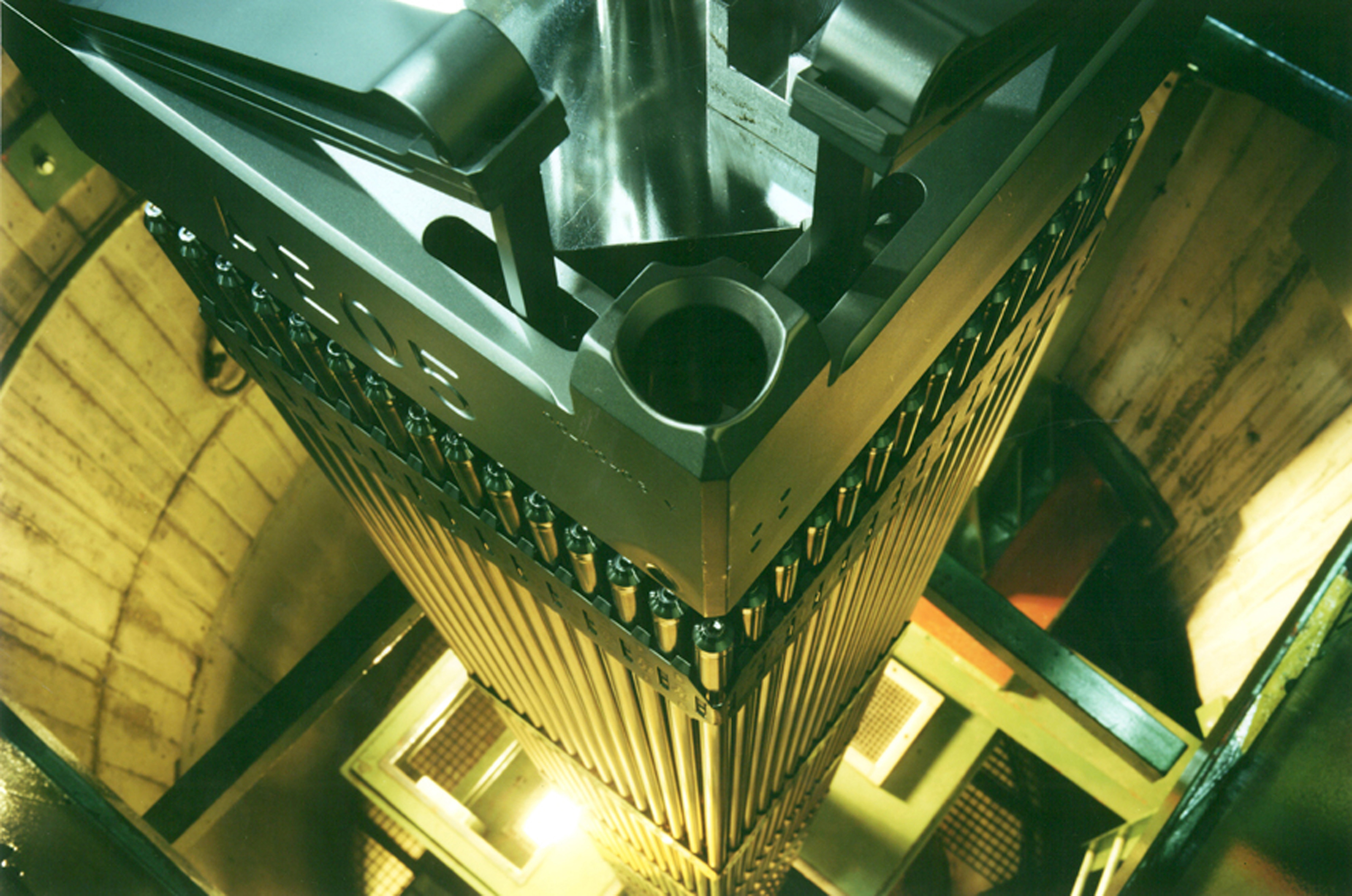

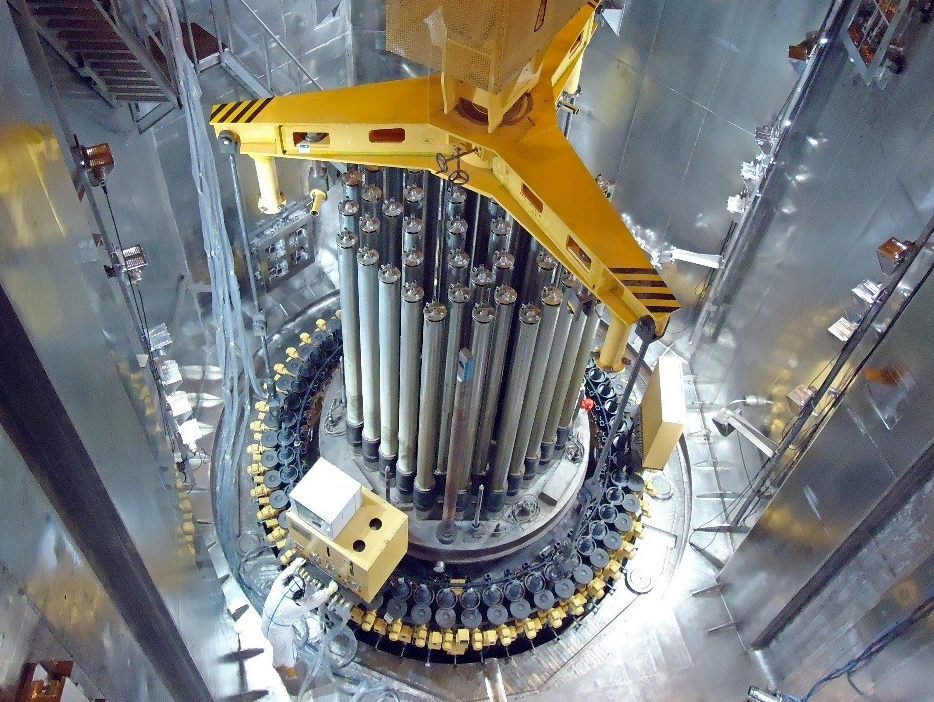

REACTOR:

Maintenance service

- Disassembly and assembly of auxiliary elements

- Reactor vessel opening and closing

- Reactor internals removal

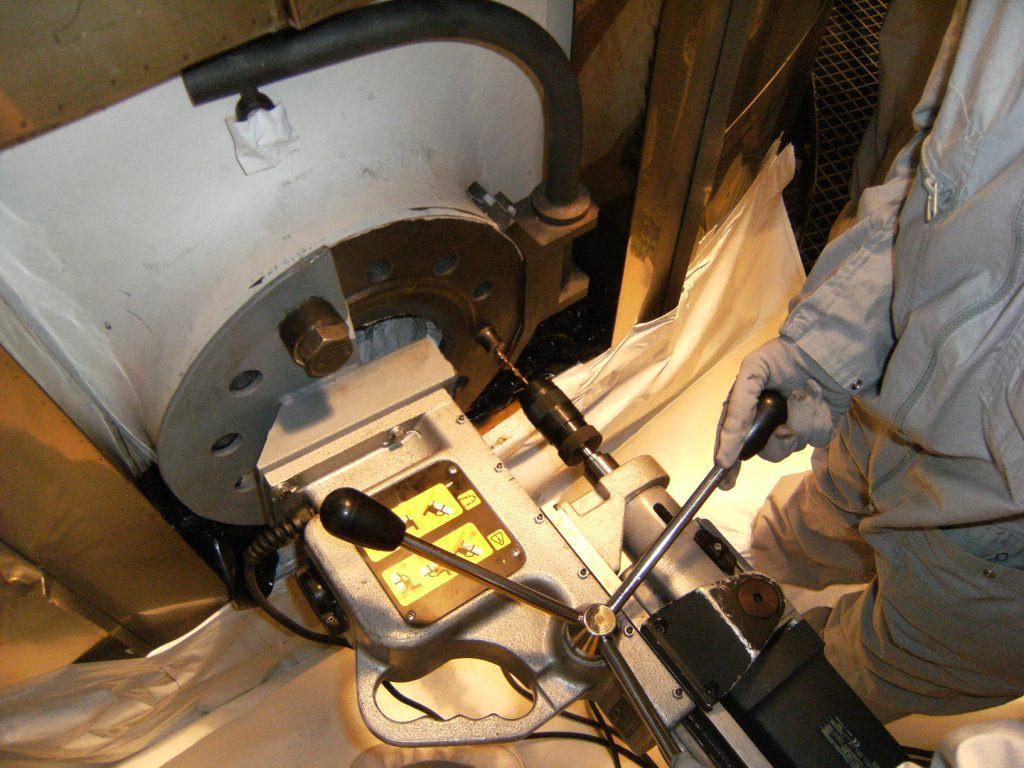

Repair service

- Replacement of guide tube pins in the lower internals

- Repair of studs and threaded holes

- Inspection, cleaning and repair of reactor vessel and reactor vessel head flanges

- Cutting and Welding

Other activities

- Extraction of irradiated samples

- Replacement of guide tubes

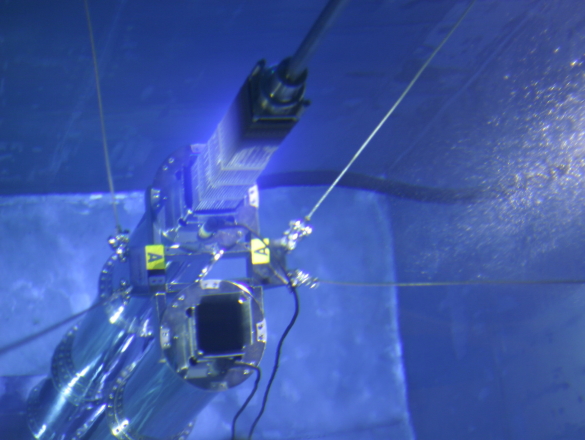

- Visual inspection of the vessel and internals

- Foreign object search and retrieval

- Tooling and equipment maintenance (bolt tensioning and threading, flange cleaning, etc.)

STEAM GENERATORS AND PRESSURIZER:

Maintenance service

- Opening and closing of manholes

- Inspection, opening and closing of the pressurizer

- Gaskets replacement

- Bolts tensioning

Repair service

- Removal of seized bolts and installation of helicoils

- Flange machining and repair

- Tube plugging (expanded and welded)

- Assembly of Nozzle Dams

Other activities

- Pressurizer heaters replacement

- Primary and secondary side inspection

- Steam generator sludge lancing

- Measurement of bolt elongation by UT

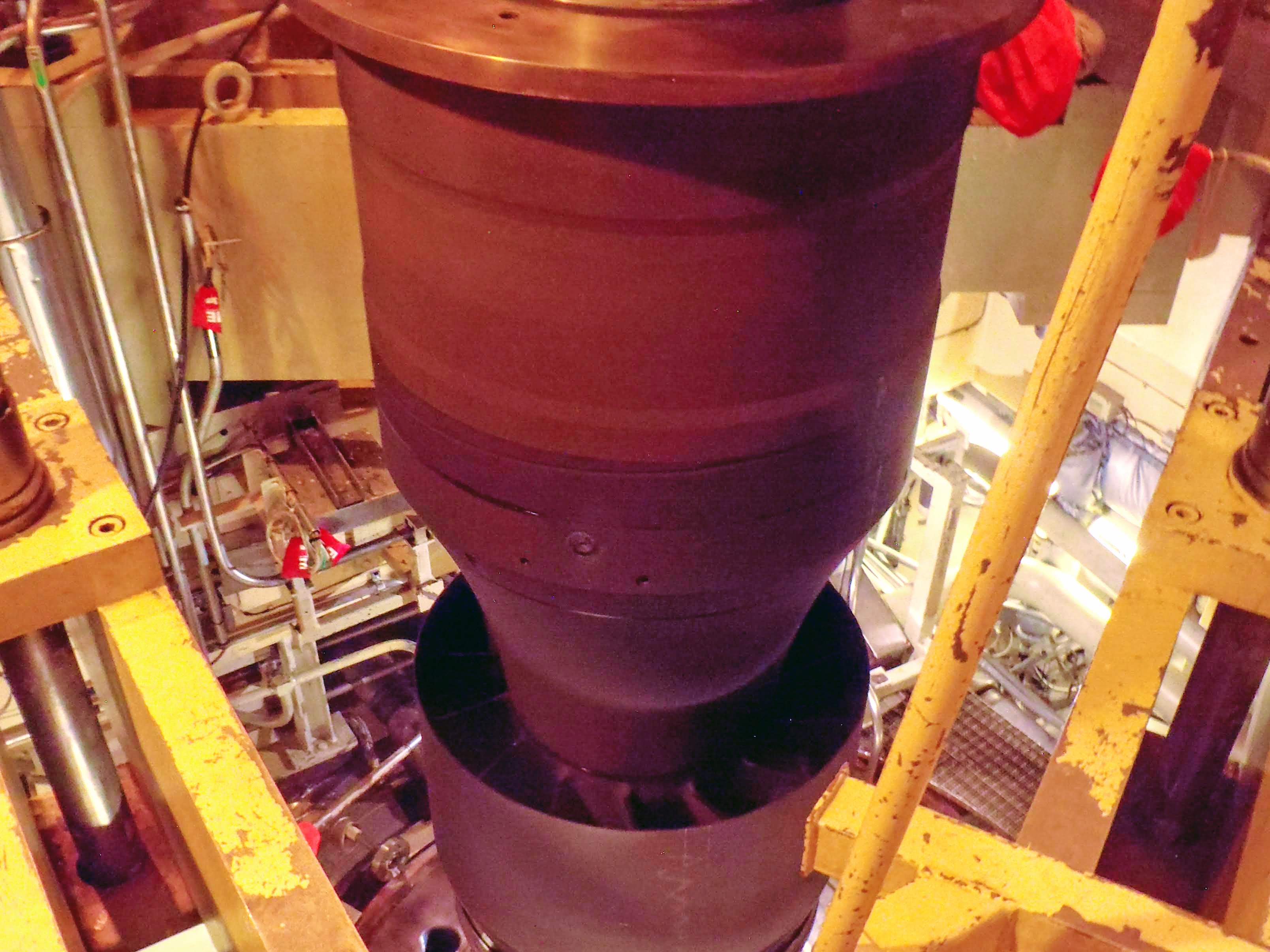

MAIN PUMPS:

- Assembly and disassembly of reactor coolant pumps and motors.

- Inspection and cleaning of components (seals, bearings, thermal barrier).

- Overhaul of associated equipment (oil lift pump, exchangers, instrumentation, etc.)

- Overhaul and change of seals.

- Overhaul of pump and motor bearings (radial and thrust).

- On-site component repair and machining.

- Inspection, cleaning and repair of bolts and housings.

FUEL:

New and spent fuel handling.

Drive shaft assembly coupling and decoupling.

Fuel inserts handling (rod control cluster assemblies, thimble plugs, burnable poisons).

Refuelling equipment check-up:

- Handling and fuel crane.

- Fuel transfer system.

- Associated tools (drive shaft assembly coupling, inserts handling.)

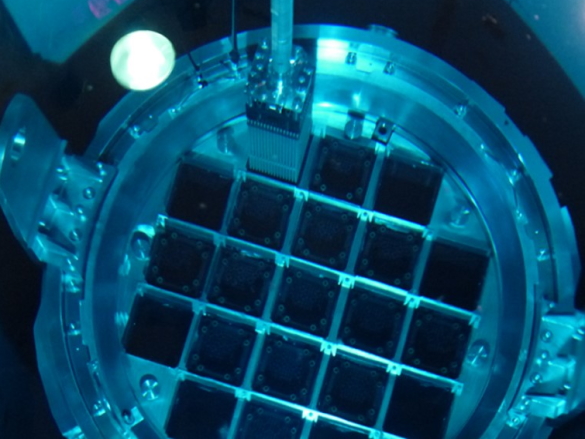

Fuel inspection:

- Leak detection by sipping and UT

- Visual inspection of fuel assemblies.

Fuel repair:

- Repair (MFRS and RTN).

- Fuel reconstruction.

- Ultrasonic fuel cleaning.

FUEL CASKS MANAGEMENT:

Container loading (ENSA-ENWESA Group):

- Handling of the casks before loading.

- Loading of spent fuel into casks.

- Closing of the cask, draining and drying process.

- Leak test.

- Cask handling and transport to temporary storage.

SPECIAL REPAIR AND OTHER ACTIVITIES:

System modifications:

- Cutting, machining and welding of equipment and systems.

- Replacement of piping.

- Design modifications.

Collaboration with ENSA:

- Laboratories (metallurgical, mechanical testing, welding, metrology, instrumentation and robotics).

- Calculation, design and development engineering.

Decommissioning activities:

Radiation protection supervision.

Welding:

- TIG, MIG and SMAW welding processes.

- Approved welding procedures.

- Qualified welders.

- Heat treatment equipment.

- Non-destructive testing and visual inspection levels 2 and 3.

Special interventions:

- Repairs and welding in Nuclear Power Plants.